Engineering in Dalby

Enquire Now in Dalby

Dalby Engineering Services

Hardarc Engineering supports clients across Dalby with tailored engineering services built for agriculture, transport, construction and mechanical maintenance. Whether we’re restoring worn equipment, fabricating a new part, or upgrading a production system, our team brings the capability to get the job done properly.

With decades of experience behind us, we help clients reduce downtime, solve recurring issues and build parts that actually fit. Call 0409 133 455 to speak with Hardarc Engineering in Dalby today.

Practical Engineering Solutions

Our team supports Dalby with practical services designed to handle tough, site-specific and time-sensitive requirements.

- Servicing Regional Operators – We work with agricultural, mechanical, civil and manufacturing clients across Dalby and surrounding areas.

- Equipped for Complex Jobs – From tight-tolerance machining to one-off fabrications, we’re set up to handle jobs with very specific requirements.

- On-Site & In-Workshop – Whether the work happens in our workshop or out in the field, we bring the right tools and experience.

- Tailored, Not Generic – Every job is approached on its own terms—no one-size-fits-all solutions, no unnecessary complications.

- Licenced & Insured – We’re fully QBCC licenced and compliant with commercial project standards.

Clients across Dalby turn to us when they need solutions that work the first time.

Enquire Now in Dalby

Address

Contact

T. 0409 133 455

Opening Hours

Mon-Fri 06:30am - 7:00pm

Sat Appointment Only

Sun Closed

Mechanical Services

With our mechanical engineering services in Dalby we support system analysis, part modification and design adjustments for improved performance and durability.

Through our automotive part repair services in Dalby, we restore worn and damaged components using precision machining and welding.

Automotive fabrication in Dalby includes custom mounts, frame reinforcements and modifications for restoration or performance-based applications.

We repair machinery in Dalby to restore function, prevent unnecessary replacement and minimise costly equipment downtime.

Fabrication & Welding

We assist with production line installations in Dalby by fitting and configuring machinery to suit operational flow and site constraints.

Through our plasma cutting services in Dalby, we produce clean, efficient cuts in steel, stainless and alloy for fabrication or part replacement.

Our specialised welding services in Dalby cover structural, alloy and stainless applications requiring strong, accurate welds.

We supply and install screw piles in Dalby for projects needing stable, low-impact foundations across industrial and rural environments.

Machining Services

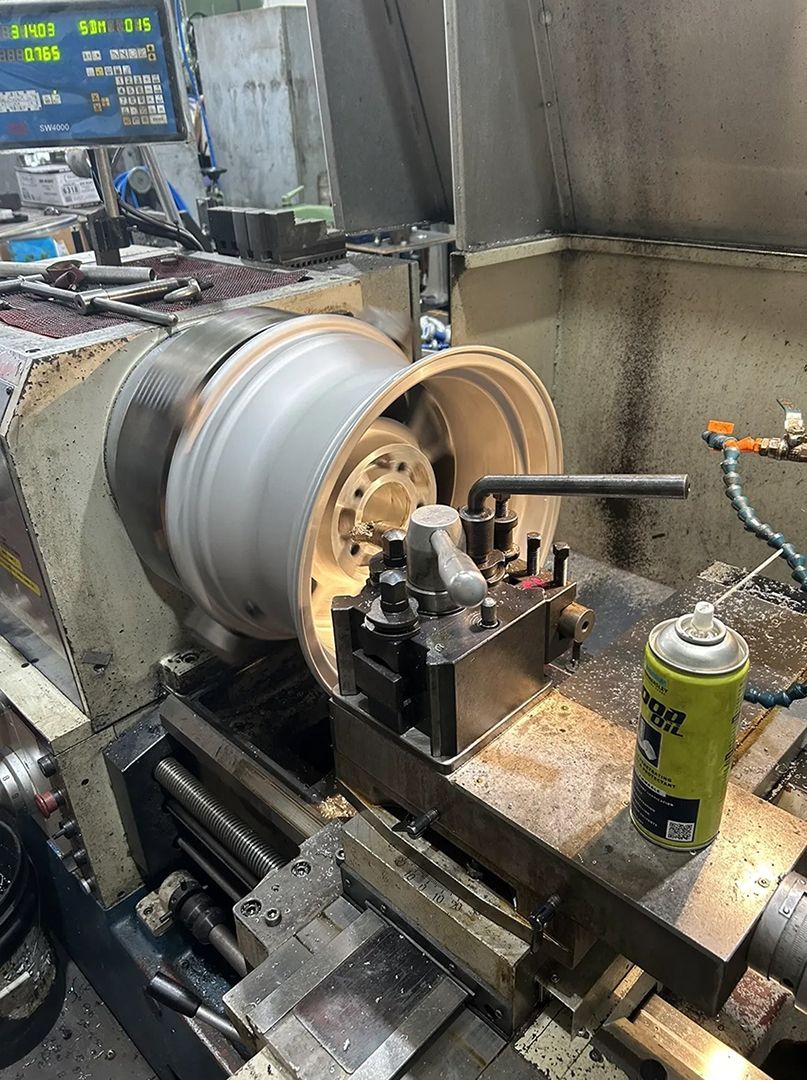

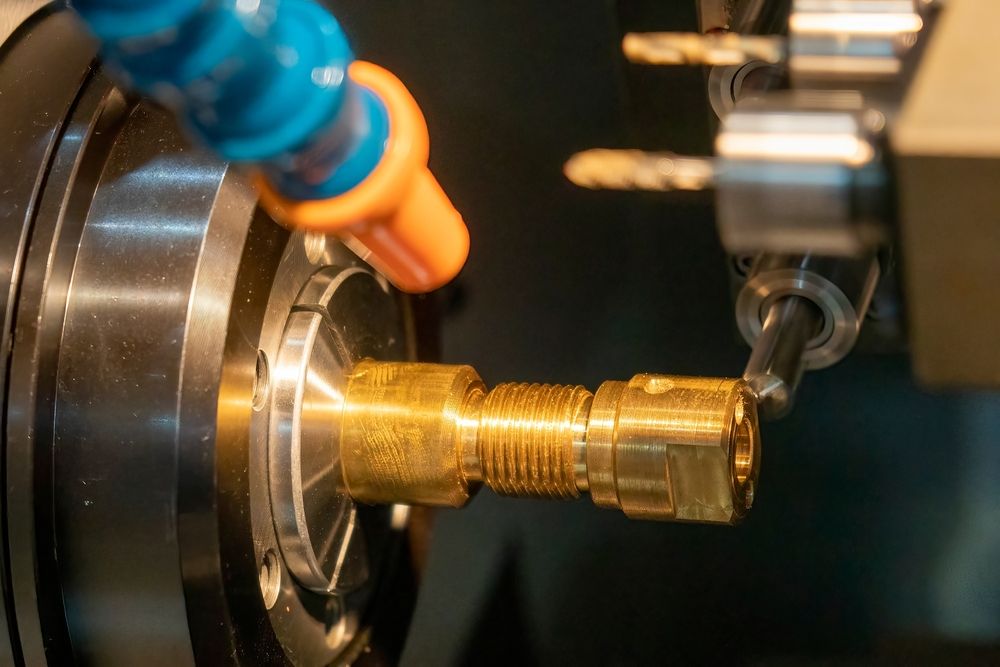

Our precision machining services in Dalby enable us to deliver exact-fit parts for repairs, system upgrades and new mechanical builds.

We carry out milling, drilling and slotting in Dolby to modify or reproduce components that require tight dimensions and clean profiles.

With our lathe metal turning services in Dalby, we shape cylindrical parts like shafts, pins and rollers to exact measurements.

Fitting and turning in Dalby supports mechanical assembly, alignment and part customisation for both new equipment and older systems.

Horizontal and vertical boring in Dalby allows us to place accurate holes through thick materials used in heavy-duty builds and structural work.